Question

What are the precautions for mounting Rotary Encoders?

Answer

Do not allow water drops or oil to come into contact with Rotary Encoders.

Rotary Encoders are made of precision components. Functionality may be damaged if they are dropped. Exercise sufficient caution when handling Rotary Encoders

If Rotary Encoders are to be used with reversible rotation, check Rotary Encoders' mounting direction and increment/decrement direction before mounting them.

Be sure to check the phase-Z output while mounting Encoders if matching the Encoders' phase-Z output with the origin of the equipment to be installed.

If a gear linkage is used, do not apply an excessive load to the shaft.

Use a tightening torque of 0.49 Nm maximum if Rotary Encoders are to be secured with screws.

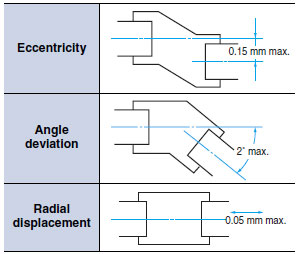

If a coupling is to be used, mount it within the range of the following allowable values.

If there is large installation error (e.g., eccentricity or declination), an excessive load will be applied to the shaft, which may result in damage or extremely shortened service life.