Multi-sensing technology

E8PC

IoT Pressure Sensors

Detect Signs of Abnormalities in Cooling Water and Hydraulic Oil by Simultaneous Measurement of “Pressure + Temperature”

about this Product Family

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: April 30, 2019

Prevents press defects and processing defects due to hydraulic pressure abnormalities

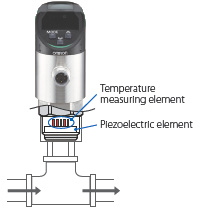

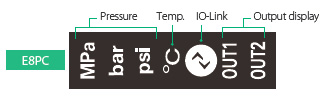

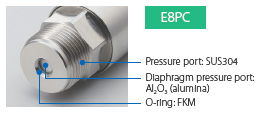

[Pressure] Uses a piezoelectric element. Since the sensing surface is made of a high-hard ceramics, it withstands high pressure.

[Temp.] Uses a temperature measuring element to measure the liquid temperature transmitted to the piezoelectric element. Uses a unique algorithm to estimate the temperature more accurately.

Pressing machine

Problems

[Press quality defects due to rises in hydraulic oil temperature]

• Rising temperatures reduce the viscosity of the hydraulic oil.

• Hydraulic pressure reduction leads to inconsistent press quality.

• You cannot detect a temperature rise by pressure monitoring alone.

Solution from OMRON

You can use signs of press pressure reduction to prevent the occurrence of product defects

With temperature monitoring, you can detect signs of abnormalities that can cause reductions in hydraulic oil viscosity.

With simultaneous monitoring of temperature and pressure in the same position, you can quantify the optimum ranges for temperature and oil pressure without relying on the experience or skills of maintenance personnel.

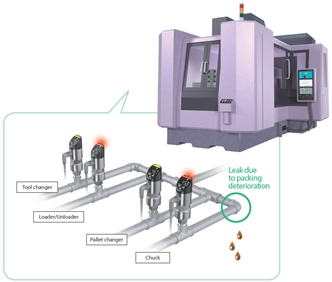

Machining center

Problems

[Tool gripping force declines due to hydraulic oil leak]

• Hydraulic oil temperature rises with repeated tool changes.

• Pipe packing deteriorates, resulting in hydraulic oil leak.

• Oil pressure reduction causes reduction in processing quality.

• The hydraulic pressure system is divided into multiple sections, so finding degraded packing locations takes time.

Solution from OMRON

You can use a rise in hydraulic oil temperature to detect signs of hydraulic oil leak

You can monitor hydraulic oil temperature changes to understand how much of a rise in temperature will have an effect on packing degradation.

By mounting sensors on multiple pipes, you can quickly tell from the sensor LED displays what abnormality has occurred, in which pipe.

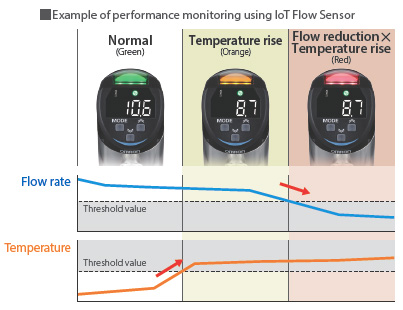

Notifications of changes in the cooling water or hydraulic oil states are easy to understand

You can see the cause of the abnormality Multi-sensing display [Patent pending]

The sensor judges by monitoring "Flow rate + Temperature" and "Pressure + Temperature". Since data outputs to a PLC by the IO-Link communications is possible, it is easy to perform maintenance before entering an abnormal state. For the display colors, you can set 3 patterns, or if combined with Not lit, a total of 4 patterns.

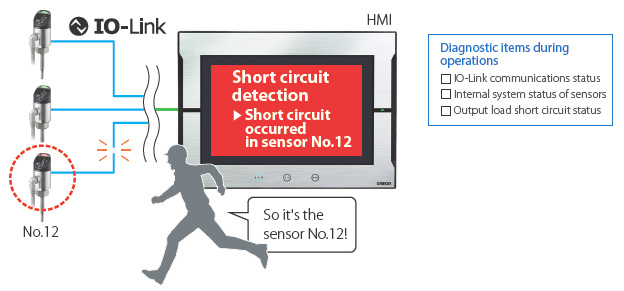

You can also see the sensor status Self-diagnostic outputs

Self-diagnoses the sensor's own status, and autonomously sends notification when signs of a connection error or a malfunction appears.

Easy to see High luminosity LED display

A high luminosity LED gives good visibility even at the back of equipment or in dark locations.

Easy to understand Display by unit

Converts to physical quantity units for display.

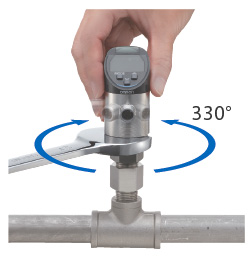

Adjust the angle according to the mounting position

Angle adjustment up to 330°

After fastening to the adapter, you can adjust the angle so that the display is easy to see.

180° reverse display

The display can rotate 180°.

Easy to use in various location

Compact and space-saving

You can even mount in narrow spaces with multiple pipes arrayed.

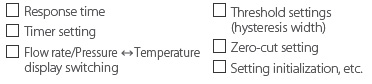

Direct setting

Button on the body for quick setting. After setting, you can use the key lock function to prevent operation in error.

Highly durable liquid contact part

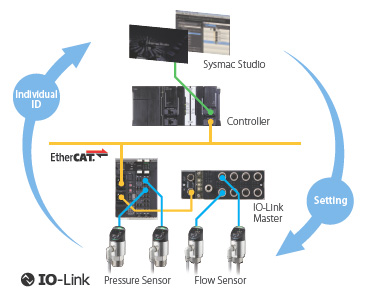

Batch setting from host devices

During maintenance, the settings must be the same conditions as when the product was initially mounted. If you use the IO-Link function, you can perform batch setting from a host device. You can manage by quantifying the adjustment that is performed by skilled personnel to avoid affecting the manufacturing quality.

Easy-to-clean structure

Structure is easily removable from the piping for periodic inspections, etc., and easily cleaned.

Expanded cable and adapter lineups (sold separately)*

* Use our dedicated adapters. In addition, if there is a possibility of pulsations or vibrations to a Pressure Sensor, we recommend the attachment of a throttle (sold separately).

last update: April 30, 2019