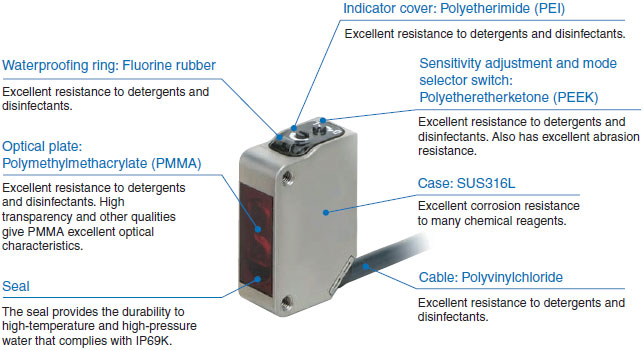

We used SUS316L for the case and the best material for all parts to achieve 200 times the durability of the E3Z (in 1.5% solution of sodium hydroxide at 70°C) to make the E3ZM suitable for the cleaning conditions of food-processing machinery.

E3ZM

Compact Photoelectric Sensor with Stainless Steel Housing

Stainless Steel Housing Ideal for Food Industry (PAT Pending)

about this Product Family

- Features

- Lineup

- Specifications

- Dimensions

- Catalog

last update: June 15, 2016

(World's Strongest)

Withstands Detergent and Disinfectant Spray

(World's First)

Superior Protective Structure

The first IP69K* (DIN 40050-9) protective structure in the world for a square metal photoelectric sensor. Suitable for high-temperature, high-pressure jet water spray cleaning applications.

* Refer to the footnote on Catalog (ratings and specifications table).

(Industry's Best)

Shape and Markings Designed for Greater Hygiene

Few indentations in the shape means less dust and water can collect, making the E3ZM more hygienic. No labels have been used in order to prevent foreign matter contaminating food products. The E3ZM model and lot numbers are imprinted using a laser marker.

Structural Design That Provides Excellent Environment-resistance*

*Do not use the E3ZM in an oily environment.

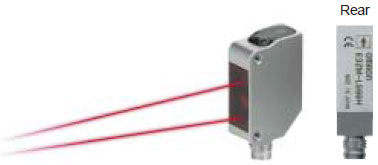

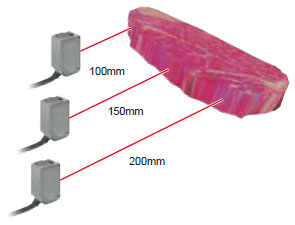

Unique Members of the E3ZM Family

BGS Reflective Models

E3ZM-LS6[]H/-LS8[]H

Three models with different fixed sensitivity (rated sensing distances) have been created. These models cover the sensing ranges of the E3Z-LS61.

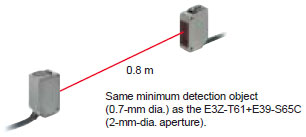

Through-beam Inner Aperture Models

E3ZM-T63

Fine beam without attaching an external aperture. This eliminates malfunctions from residual water drops, even immediately after washing.

A Better Fit for the Application

The E3ZM can be used in those harsh cleaning environments in which the E3Z was difficult to use. E3ZM passed the material resistance tests and is certified by Ecolab.

last update: June 15, 2016