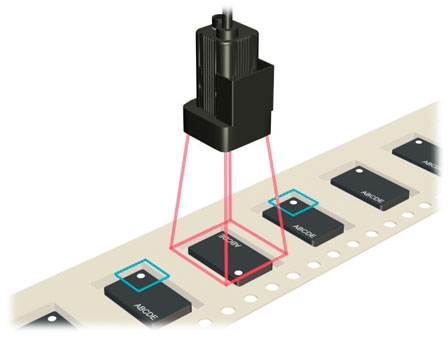

Image Sensors Used to Stably Determine Passing or Failure of Workpieces on Rapidly Conveyed Lines

Case Number 233

last update: April 18, 2011

This Image Sensor has improved pattern matching. This also enables handling rapidly moving workpieces such as those in mounting of embossing tape conducted in the latter processes of semiconductor manufacturing. The front and back of electronic components and the difference between different models are measured and in comparison with non-defective items to enable stable detection of mounting errors.

Know-How

The unique image processing circuits support high-speed lines performs matching with models dividing images into smaller parts. Subtle differences that cannot be determined by conventional pattern matching are detected as large numerical values.

Benefit / Efficiency

Detection of irregularities on embossing tape prevents problems on customer lines and in products.

-

- Industry

-

Semiconductors / Electronics

Semiconductors / Electronics

-

- Work / Process

-

Inspection / Measurement

Inspection / Measurement

-

- Product Category

-

Vision Sensors / Machine Vision Systems

Vision Sensors / Machine Vision Systems

Use Products

Smart Sensor (Vision sensor with built-in LCD monitor)

ZFX

Smart Sensor (Vision sensor with built-in LCD monitor)

ZFX

Essential Innovation for Future Generations

About this Application Case

Applications

Applications

Industry

Industry Semiconductors / Electronics

Semiconductors / Electronics- Image Sensors Used to Stably Determine Passing or Failure of Workpieces on Rapidly Conveyed Lines