RFIDs for PWB Mounting Process Management

Case Number 217

last update: April 19, 2011

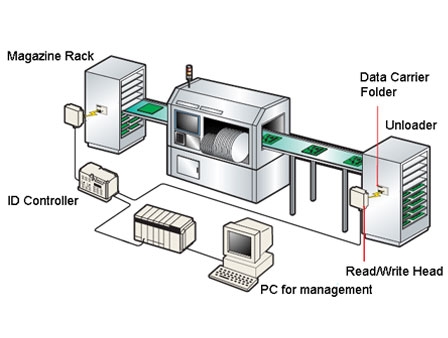

RFID Tags (IC tags) that are attached to magazine racks store PWB information, such as lot number, model, PWB size, and number of boards. Setup changes are also performed during mounting based on information in RFID Tags (IC tags).

Completion information and information on the PWBs that are used are written to the RFID Tags (IC tags) on magazine racks when mounting is completed.

Inspection results (pass/fail) are written to RFID Tags (IC tags) in the inspection process, and failed items are fed back to the revision process.

Completion information and information on the PWBs that are used are written to the RFID Tags (IC tags) on magazine racks when mounting is completed.

Inspection results (pass/fail) are written to RFID Tags (IC tags) in the inspection process, and failed items are fed back to the revision process.

Know-How

RFID Tags (IC tags) that are attached to magazine racks store PWB information, such as lot number, model, PWB size, and number of boards. Setup changes can also be automated. The results of inspection processes are written to RFID Tags (IC tags), which simplifies the feedback of information for management of production history and revisions.

Benefit / Efficiency

This eliminates mistakes in setup changes, and prevents careless mistakes because mounting history information is collected automatically.

The need for administration computers for PWB magazine racks is reduced compared with bar codes.

Support for flexible production is provided by ‘urgent flags’ in RFID Tags (IC tags) on magazine racks. This enables management that can flexibly support diversification and reduced delivery times.

The need for administration computers for PWB magazine racks is reduced compared with bar codes.

Support for flexible production is provided by ‘urgent flags’ in RFID Tags (IC tags) on magazine racks. This enables management that can flexibly support diversification and reduced delivery times.

-

- Industry

-

Semiconductors / Electronics

Semiconductors / Electronics

-

- Work / Process

-

Control

Control

-

- Product Category

-

RFID Systems

RFID Systems

Use Products

RFID System

V680 series

RFID System

V680 series

RFID Systems with ISO/IEC 18000-3 (15693) Compliance

About this Application Case

Applications

Applications

Industry

Industry Semiconductors / Electronics

Semiconductors / Electronics- RFIDs for PWB Mounting Process Management