RFIDs for Hard Disk Manufacturing Process Management

Case Number 216

last update: April 19, 2011

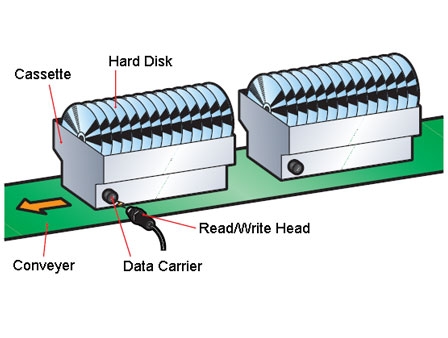

RFID Tags (IC tags) are attached to special cassettes that contain tens of hard disks.

Product information, lot information, work instructions for each process, process completion flags, and instructions for the next process are written to RFID Tags (IC tags).

Information in RFID Tags (IC tags) is read by the Read-Write Heads installed on the equipment in each process, and processing and inspections are performed based upon this information. Pass/fail information from inspection results is written in the inspection process.

When work is completed in each process, the process completion flag and instructions for the next process are written.

In the final process, all information in the RFID Tags (IC tags) is read and stored in the administration computer as lot management data.

Product information, lot information, work instructions for each process, process completion flags, and instructions for the next process are written to RFID Tags (IC tags).

Information in RFID Tags (IC tags) is read by the Read-Write Heads installed on the equipment in each process, and processing and inspections are performed based upon this information. Pass/fail information from inspection results is written in the inspection process.

When work is completed in each process, the process completion flag and instructions for the next process are written.

In the final process, all information in the RFID Tags (IC tags) is read and stored in the administration computer as lot management data.

Know-How

The RFID Tags (IC tags) are heat resistant to 180℃. The same tags are used throughout all processes, including high temperature locations such as drying processes.

Benefit / Efficiency

The use of RFID Tags (IC tags) with excellent environmental resistance enables reliable monitoring of lot information and process information in each process. It is possible to improve and maintain yield.

Process history information is written whenever necessary to enable reliable traceability within processes. The administration computer system is also simplified.

Process history information is written whenever necessary to enable reliable traceability within processes. The administration computer system is also simplified.

-

- Industry

-

Semiconductors / Electronics

Semiconductors / Electronics

-

- Work / Process

-

Control

Control

-

- Product Category

-

RFID Systems

RFID Systems

Use Products

RFID System

V680 series

RFID System

V680 series

RFID Systems with ISO/IEC 18000-3 (15693) Compliance

About this Application Case

Applications

Applications

Industry

Industry Semiconductors / Electronics

Semiconductors / Electronics- RFIDs for Hard Disk Manufacturing Process Management