RFIDs Used to Manage Liquid Crystal Manufacturing

Case Number 212

last update: April 19, 2011

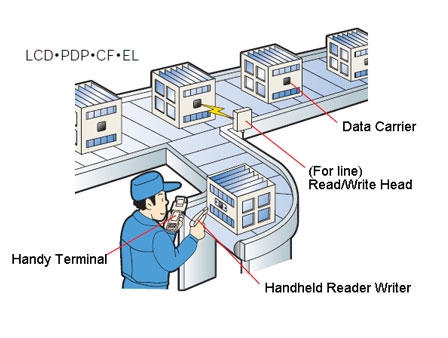

Work instructions are stored in ID Tags that are attached to cassettes. They store model information, process instructions, process completion information, substrate information, and inspection results. The necessary information is read from RFID Tags (IC tags) when required.

Know-How

RFID Tags (IC tags) that provide excellent environmental resistance (such as water resistance, chemical resistance, and long service life) as well as reliable reading and writing are attached to cassettes.

Benefit / Efficiency

There is no need for interaction between bar codes and administration computers in each instance, and this simplifies the production program and system.

They provide highly reliable reading and writing, which eliminates line stoppages caused by errors.

RFID Tags (IC tags) uses non-contact communications and so there are no particles or other matter generated, contributing to a higher yield rate.

Replacing bar code labels and other similar kinds of maintenance are not required, enabling reductions in running costs.

They provide highly reliable reading and writing, which eliminates line stoppages caused by errors.

RFID Tags (IC tags) uses non-contact communications and so there are no particles or other matter generated, contributing to a higher yield rate.

Replacing bar code labels and other similar kinds of maintenance are not required, enabling reductions in running costs.

-

- Industry

-

Semiconductors / Electronics

Semiconductors / Electronics

-

- Work / Process

-

Control

Control

-

- Product Category

-

RFID Systems

RFID Systems

Use Products

RFID System

V680 series

RFID System

V680 series

RFID Systems with ISO/IEC 18000-3 (15693) Compliance

About this Application Case

Applications

Applications

Industry

Industry Semiconductors / Electronics

Semiconductors / Electronics- RFIDs Used to Manage Liquid Crystal Manufacturing