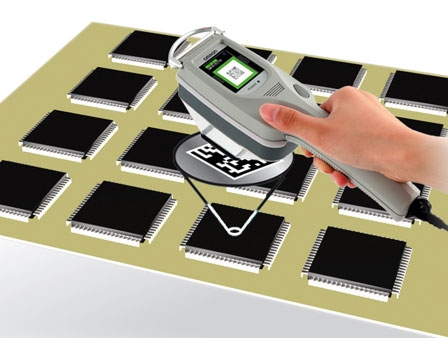

Random Sampling of Electronic Components in a Clean Room

Case Number 209

last update: April 1, 2008

Two-dimensional codes containing product information, such as serial numbers and feature values, are printed onto components by direct marking.

This data is read during inspections, and saved onto an SD card together with the inspection results.

When the work is completed, the saved log is transferred to a database.

This data is read during inspections, and saved onto an SD card together with the inspection results.

When the work is completed, the saved log is transferred to a database.

Know-How

By writing product information into 2-dimensional codes, a large amount of data can be written in a small amount of space.

The handheld reader is ideal for use in cell production processes.

The monitor and SD card slot make it possible to check data and save logs without having to bring a laptop computer into the Clean Room.

The handheld reader is ideal for use in cell production processes.

The monitor and SD card slot make it possible to check data and save logs without having to bring a laptop computer into the Clean Room.

Benefit / Efficiency

Accurately controlling the product's inspection results allows a fast response to be made in the event of a recall.

This helps to minimize the amount of equipment brought into the Clean Room and prevents the degree of cleanness from being reduced.

This helps to minimize the amount of equipment brought into the Clean Room and prevents the degree of cleanness from being reduced.

-

- Industry

-

Semiconductors / Electronics

Semiconductors / Electronics

-

- Work / Process

-

Control

Control

-

- Product Category

-

Code Readers / OCR

Code Readers / OCR

Use Products

Handheld 2D Code Reader

V400-H

Handheld 2D Code Reader

V400-H

A New Handy Reader Capable of Reading Directly Marked Codes

About this Application Case

Applications

Applications

Industry

Industry Semiconductors / Electronics

Semiconductors / Electronics- Random Sampling of Electronic Components in a Clean Room