Question

What is IP-[][]?

Answer

Degree of Protection

Note:IP-[][] degrees of protection given in this document were confirmed by OMRON based on the test conditions given below. Confirm satisfactory sealing performance in the actual operating environment and under the actual operating conditions before use.

IEC (International Electrotechnical Commission) Standards (IEC 60529 2001)

First symbol: Degree of protection against solid materials

| Degree | Protection | |

| 0 |  | No protection |

| 1 |  | Protects against penetration of any solid object such as a hand that is 50 mm or more in diameter. |

| 2 |  | Protects against penetration of any solid object that is 12.5 mm or more in diameter. Any object with a diameter of 12 mm, such as a finger, will not reach a hazardous part even if it penetrates 80 mm. |

| 3 |  | Protects against penetration of any solid object such as a wire that is 2.5 mm or more is diameter. |

| 4 |  | Protects against penetration of any solid object such as a wire that is 1 mm or more in diameter. |

| 5 |  | Protects against penetration of dust of a quantity that may malfunction the protect or obstruct the safety operation of the product. |

| 6 |  | Protects against penetration of all dust. |

Second symbol: Degree of protection against water

| Degree | Protection | Test method (with pure water) | ||

| 0 | No protection | Not protected against water. | No test | |

| 1 | Protection against water drop  | Protects against vertical drops of water towards the product. | Water is dropped vertically towards the product from the test machine for 10 min. |  |

| 2 | Protection against water drops  | Protects against drops of water approaching at a maximum angle of 15° to the left, right, back, and front of vertical towards the product. | Water is dropped for 2.5 min each (i.e., 10 min in total) towards the product inclined 15° to the left, right, back, and front from the test machine. |  |

| 3 | Protection against sprinkled water  | Protects against sprinkled water approaching at a maximum angle of 60° from vertical towards the product. | Water is sprinkled at a maximum angle of 60° to the left and right from vertical for 10 min from the test machine. |  |

| 4 | Protection against water spray  | Protects against water spray approaching at any angle towards the product. | Water is sprayed at any angle towards the product for 10 min from the test machine. |  |

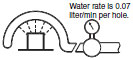

| 5 | Protection against water jet spray  | Protects against water jet spray approaching at any angle towards the product. | Water is jet sprayed at any angle towards the product for 1 min per square meter for at least 3 min in total from the test machine. |  |

| 6 | Production against high-pressure water jet spray  | Protects against highpressure water jet spray approaching at any angle towards the product. | Water is jet sprayed at any angle towards the product for 1 min per square meter for at least 3 min in total from the test machine. |  |

| 7 | Protection underwater  | Resists the penetration of water when the product is placed underwater at specified pressure for a specified time. | The product is placed 1 m deep in water (if the product is 850 mm max. in height) for 30 min. |  |

| 8 | Protection underwater  | Can be used continuously underwater. | The test method is determined by the manufacturer and user. | |

IP69K Degree of Protection

IP69K is a standard for protection again ingress of high-temperature, high-pressure water defined in the German standard DIN 40050 Part 9. The test piece is sprayed with water at 80° at 80 to 100 bars with a nozzle of the specified shape. The water volume is 14 to 16 l/min. The test piece is separated from the nozzle by 10 to 15 cm and water is sprayed for 30 s each at 0°, 30°, 60°, and 90° while the test piece is rotated on a horizontal plane.

*1.OMRON Test Methods

The Proximity Sensor’s IP67 degree of protection was confirmed by performing the tests described in the table below and making sure that the sensing distance and installation resistance satisfied the performance specifications after repeating a heat shock cycle 5 times, consisting of immersing the Sensor in cold water at 0°C for 1 hour followed by hot water at 70°C for 1 hour.

*2.Precautions on OMRON Testing

Operating conditions for E2F Proximity Sensors: Underwater within 10 m

(1)No penetration of water when immersed in water for 1 hour at an atmospheric pressure of 2

(2)Satisfies sensing distance and insulation resistance performance specifications after the heat shock cycle described in *1 is repeated 20 times

In-house Standards for Oil Resistance

| Degree of protection | |

| Oilproof | No harmful effect when subjected to oil drops or oil spraying from any direction. |

| Oil-resistant | No penetration into internal parts when subjected to oil drops or oil spraying from any direction. |

Note:Oil resistance is confirmed using oils and cutting oils stipulated by OMRON (equivalent to previous JEM standards).