RFIDs Used to Manage Home Appliance Manufacturing Process

Case Number 196

last update: April 19, 2011

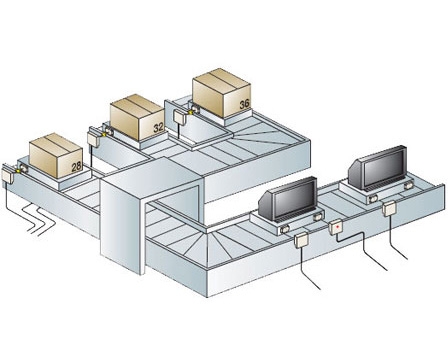

Product information, processing information, assembly information, and inspection information are written to RFID Tags (IC tags) that are attached to pallets.

Processing, assembly, inspection, and sorting are performed in each process according to the work instructions on RFID Tags (IC tags).

Inspection results are written to RFID Tags (IC tags) in each inspection process, and gathered into a management computer in the final process.

Processing, assembly, inspection, and sorting are performed in each process according to the work instructions on RFID Tags (IC tags).

Inspection results are written to RFID Tags (IC tags) in each inspection process, and gathered into a management computer in the final process.

Know-How

These RFID Tags (IC tags) have excellent environmental resistance for stable communications even in FA sites.

These highly reliable RFID Tags (IC tags) retain reliable data even in inspection processes that use tens of thousands of volts and strong electrical fields.

These highly reliable RFID Tags (IC tags) retain reliable data even in inspection processes that use tens of thousands of volts and strong electrical fields.

Benefit / Efficiency

The setup is changed efficiently in each process because products and information are centrally managed.

Product traceability is managed reliably because the collection of manufacturing history and inspection history is automated.

Product traceability is managed reliably because the collection of manufacturing history and inspection history is automated.

-

- Industry

-

Home Electronics / Office Automation

Home Electronics / Office Automation

-

- Work / Process

-

Control

Control

-

- Product Category

-

RFID Systems

RFID Systems

Use Products

RFID System

V680 series

RFID System

V680 series

RFID Systems with ISO/IEC 18000-3 (15693) Compliance

About this Application Case

Applications

Applications

Industry

Industry Home Electronics / Office Automation

Home Electronics / Office Automation- RFIDs Used to Manage Home Appliance Manufacturing Process